Calcium Hypochlorite: Diving Into Its Story and Real-World Value

How Calcium Hypochlorite Changed Lives

Generation after generation, people have hunted for simple ways to keep water safe and diseases at bay. Around the early 1900s, folks noticed that chlorine did wonders against bacteria and viruses. Along came calcium hypochlorite, a punchy white powder that made water disinfection far more manageable. Folks living near rivers or lagging city pipes suddenly gained a low-cost option for cleaner water, which steered communities away from large-scale outbreaks of diseases like cholera and typhoid. During the push for public pool safety and widespread sanitation, this stuff became a quiet ally, passed from hand-to-hand in buckets, sacks, and later, pressed tablets. Decades on, its value only grew, not just on the farm or plant floor, but in emergency kits sent to disaster sites. Watching it cross into labs, factories, and city water systems, you can see that one bright powder can change more than just science—it can shrink worries about survival and sickness, too.

Getting to Know the Product

Search the hardware aisles or water-treatment shelves, calcium hypochlorite stands out. Most folks spot it as a ready-mix powder or solid granules, a breeze to toss into water tanks or pools. Straight out of the bag, it gives off a strong bleach-like odor and kicks up visible dust. It doesn’t hide its power—nearly 65% of its weight packs reactive chlorine, giving each scoop real muscle in killing off germs and algae. Over the years, companies have spun out various grades: high-strength versions for industrial use, smoother blends for household tasks and pools, and slow-release forms for steady water towers. The label runs a hefty name—calcium hypochlorite—but people might also call it “bleaching powder” or by brand names like HTH, Perchloron, or Chloride of lime. No matter the name, the job stays the same: knock down the bad stuff that lurks in water and leave it safe to drink, swim, or wash with.

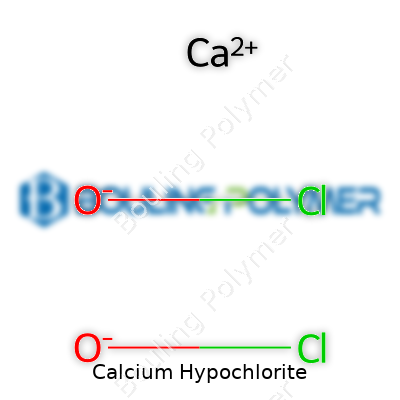

Physical Looks and Chemical Make-Up

Hauling a sack of calcium hypochlorite feels much like scooping up sugar, though the powder itself is snow white to greyish, gritty, and sometimes a little clumpy from humidity. Drop some in a beaker of water, bubbles froth up fast, and you catch a whiff of chlorine. On paper, its formula reads Ca(OCl)2, folding together calcium, oxygen, and chlorine atoms. This blend gets a spot in the high-energy crowd: dry samples burn quick with organic stuff, and a little moisture only jump-starts the process—giving it a reputation for being unstable when not kept cool and dry. In humid weather, the powder wants to draw water out of the air, sometimes clumping or losing some punch as it sits. If you ever handled it on a hot day, you know the sting on the nose is real. But the same strength that keeps germs on their toes also demands respect from anyone who opens the lid.

What the Label Tells You

Most bags and canisters line up clear numbers and warnings. Pure calcium hypochlorite clocks in around 65-70% available chlorine, though the market also pushes lower grades at about 35%. Labels spell out not just the chemical content, but storage advice: keep it dry, seal it tight, steer clear of acids, flammable materials, and metals. Transport and commercial sales follow UN code 1748, flagging it as an oxidative hazard. Wear gloves, avoid breathing dust, and don’t let it spill—each guideline comes from old stories of mishaps in the plant yard or by the pool filter. The right packaging fights off moisture: lined drums or specialty plastic do the heavy lifting, backed up by clear batch numbers and expiry dates to keep users in the know.

How It’s Made—A Real-World Method

The factory floor echoes with the hiss and fizz of gas—making calcium hypochlorite means bubbling chlorine gas through slaked lime (calcium hydroxide), often in big, sealed tanks. Chemists learned over decades that careful control of temperature and reaction speed matters; rush this step, and the powder might lose strength or smell sharp from leftover lime. After the main reaction finishes, workers filter and dry the solid mixture, grind it down, and often blend it to meet industrial standards. Clever tweaks, such as protecting it from excess air, remove leftover moisture and help the final product resist caking in humid air. Each batch rolls out for chemical checks, weighed against specs not just for strength, but also for traces of unwanted ingredients—which can make a world of difference, especially for drinking water.

Chemical Reactions and Tweaks

Drop calcium hypochlorite into water, it breaks up to release hypochlorous acid—the real germ killer—along with calcium ions. Too much acid, such as vinegar or pool pH drop, pushes the reaction further, causing a nose-burning release of chlorine gas. Mix it with organic matter, see heat and sometimes fire follow. On a commercial level, manufacturers dial in stabilizers to slow the loss of chlorine over time, making the product shelf-friendly and safer to handle long-term. In labs, folks have rigged up reactions that swap out lime for other calcium sources, fine-tuning purity or cost. Some recent efforts focus on blending in anticaking agents, which keep granules loose regardless of the drippy summer air.

Names You’ll Find and Brands People Trust

Calcium hypochlorite goes by more than one face: water disinfection circles still call it “bleaching powder,” while the chemical world might shorthand it to Ca(OCl)2. Older records mention “chlorinated lime,” and folks in the pool supply trade talk about “pool shock” or rattle off names like HTH, Perchloron, and Pittchlor. This jumble of names sometimes trips up new buyers, leading to mistakes as folks confuse it with basic limestone, calcium chloride, or even other pool chemicals like sodium hypochlorite (liquid bleach). Clear branding and good warehouse labeling save time and hassle for everyone, especially during emergencies or big municipal runs.

Safe Handling and Workplace Standards

Experience shows mishandling this stuff leads to real harm: skin burns, bad coughs, and even toxic gas clouds mixing with the wrong cleaners. Modern safety sheets call out gloves, face masks, splash goggles, and steady ventilation as staples wherever the powder gets loaded or mixed. In my time at an industrial site, one forgotten mask spelled allergic rashes on half a crew. Storage away from flammables and acids remains a non-negotiable: news stories of warehouse fires make the local news all too often, thanks to “ordinary” bleaching powder kept next to paint or fertilizer. Industry keeps a close eye on spill kits, dousing unwanted leaks with lots of water and neutral stuff like sand or soda ash. Good training and clear signage—simple, bold warnings in big letters—turn out safer than thick binders of rules nobody reads.

Where Calcium Hypochlorite Puts in the Work

The reach of this chemical feels bigger than most people guess. Water treatment plants, both city and rural, call on it every day to blitz bacteria and parasites before anyone turns on the tap. Swimming pool owners toss in a handful weekly, watching crystal-clear water stay safe through sticky summers. Crisis teams haul drums to disaster zones or flood-hit towns, helping families turn muddy water drinkable. Farmers rely on it for disinfecting animal shelters and milking stations, while restaurant crews scrub floors with it in the late hours. A few industrial plants use it to destroy traces of cyanide or clean up effluent before it hits the drain. In my work with rural NGOs, handing out easy-to-store packets of calcium hypochlorite made more sense than teaching folks to handle liquid bleach—especially where power kicked out or shelves stayed bare.

Research and Development Unfolds

Researchers keep looking for ways to cut down the risks and boost the punch of calcium hypochlorite. Studies in recent years focus on finding coatings or blends that help the chemical ride out months-long journeys through hot climates. Others are testing smaller, smarter tablet forms that never clump, dissolve faster, or give out more accurate doses in bad weather and emergencies. There’s a real race to improve lingering shelf-life and reduce the formation of unwanted byproducts like trihalomethanes, which raise alarms about possible cancer links if they wind up in tap water. Some groups in Asia and Africa have been trialing hand-powered dispensers and portable test kits that strip out guesswork in dosing, closing the knowledge gap for small communities and families. Listening to engineers, project managers, and field workers talk about “the next big thing” often ends in excitement about topping up chlorine levels with less waste, safer hands, and steadier supply chains.

Toxicity—What the Science Says

Anybody who has inhaled a deep whiff of this powder remembers the burning throat and watering eyes—it brings a sharp warning to anyone getting careless. Chlorine compounds like this one kill pathogens aggressively, but the same action can irritate lungs, skin, and eyes in people. Mixing even small amounts with household acids or ammonia sometimes triggers toxic gas releases. Overexposure in the workplace sometimes ties to asthma or lung problems. Animals, especially cats and dogs, risk poisoning from chewing lumps or lapping the runoff. Over long periods, trace byproducts from drinking treated water are under watch, tied in some studies to higher cancer rates. Regulators worldwide have capped safe intake, and watchdog agencies run ongoing toxicology screens to keep up with strange cases. Workplaces that keep fresh air flowing and those that push for safer training see fewer problems—and more confidence on crew lines.

Looking Ahead: The Future for Calcium Hypochlorite

Plenty of hurdles lie ahead. Growing cities want water that’s safer and tastes better. People lean toward green products, asking if cheap chlorine can work without creating risky byproducts. Startups look to smart package designs—single-dose, leakproof, shelf-stable for years—and search for processes that do more with less waste. Some breakthrough work uses renewable feedstocks or new blending techniques to make this old standby less polluting at the factory and safer out in the field. Scientists track whether adding silver or blending in non-chlorine boosts can cut the chlorine load, maybe making each bucket or tablet go further. Emergency planners and humanitarians imagine smart sensors that dispense the right dose based on water quality by the minute, stripping away “guesstimate” doses and making every gallon count. Despite fancier filter tech and designer chemicals in the works, calcium hypochlorite stands strong, mainly because it matches up cost, punch, and ease for every corner of the globe.

Meeting Health Needs with Simple Chemistry

Open the lid on most communal pools and a faint, sharp scent fills the air. That smell comes from calcium hypochlorite. I grew up spending summers at public pools where, once in a while, the water shimmered a little too brightly and my skin felt just a hint drier than usual. Later, I learned that this powder didn’t just keep the water looking inviting—it kept us all from catching a stomach bug. Calcium hypochlorite packs a punch as a disinfectant and keeps bacteria and viruses at bay, especially in hot, crowded water.

Water Disinfection in Emergencies and Daily Life

Plenty of towns, especially those dealing with outdated infrastructure, use calcium hypochlorite in their municipal water treatment. After natural disasters, safe water can make the difference between a quick recovery or a new health crisis. Aid organizations often choose calcium hypochlorite for purifying water in emergencies. A simple scoop can make dirty or suspect water much safer to drink. The World Health Organization lists it as a practical way to fight cholera, typhoid, or dysentery after floods or earthquakes.

Everyday Use Around the Home and Workplace

Schools, hotels, hospital laundry rooms and dairy farms share one rule—germs don’t get a free pass. Calcium hypochlorite powers sanitation routines in these spaces. My neighbor, a dairy farmer, keeps a stash handy to clean his milking machines. It stops mold and harmful bacteria from spreading and helps produce safer milk. Hospital staff rely on it for disinfecting linens. Even my local food trucks use it for sanitizing cutting boards and prep counters.

Safety and Storage Concerns

This chemical can save lives, but it earns respect in the storage closet. My high school janitor used to warn us—mix it with the wrong thing and the results could be dangerous. Calcium hypochlorite reacts quickly with common cleaners like ammonia or acids, sometimes producing toxic gas. Even just heat or moisture can trigger a fire. For this reason, health guidelines keep it in cool, dry corners, far from other supplies. Education and strict handling rules keep staff and families safe.

Potential Solutions for Safer Handling

Some groups look for less hazardous disinfectants, but few match this substance’s powerful action. Automated dosing systems take guesswork out of the process and lower the chance human error will cause trouble. Simple training programs in schools and businesses help everyone spot hazards and know how to handle spills and accidental exposure. Signs posted in storage rooms, paired with clear labeling, encourage safe choices even during a busy day.

Balancing Need and Careful Use

Calcium hypochlorite plays a vital role in health and safety, especially where clean water is not a guarantee. In homes, hospitals, farms, and public spaces, it fights invisible threats that many might forget until illness strikes. By matching its strong disinfecting power with careful storage and training, we get the best of both worlds—cleaner environments and fewer risks to people nearby.

Why Storage Matters

Years of using pool disinfectants and cleaning chemicals taught me this: calcium hypochlorite demands respect. This common sanitizer packs a strong punch, capable of powering through algae and bacteria. The very quality that makes it popular also brings risks. If you ignore those, you’re asking for trouble in a hurry.

Storing Calcium Hypochlorite: Real Risks

Look at any news story involving fires at pool supply stores or chemical warehouses, and calcium hypochlorite often appears in the investigation reports. The U.S. Chemical Safety Board documented several fire incidents linked directly to improper storage. In every single example, heat buildup, moisture leaks, or accidental mixing with organic substances led to explosions or toxic gas releases.

I once visited a public pool’s maintenance area and found it cluttered with boxes stacked near bags of fertilizer and opened cleaning bottles. A recipe for disaster, and not just because regulations demand more care. Mixing this oxidizer with any organic or combustible material, even by accident, can set off a fire that the local news will be talking about for weeks.

Keeping It Dry and Cool Makes All the Difference

Humidity sneaks in easily, especially during summer months or in basements without good airflow. Calcium hypochlorite reacts quickly with water, releasing chlorine gas. The chemical doesn’t care if it’s a leaky bag or a thirsty Florida afternoon — so a dry spot, away from sinks, mop buckets, and wet walls, matters. If you store the chemical near these things, it’s only a matter of time before corrosion or drips take over.

I never trust cardboard for sitting chemicals. Plastic bins with tight lids keep moisture out and add a layer of separation — not just from water but from other chemicals. Metal shelves and bins here can also rust or spark reactions, so I pick plastic or fiberglass whenever possible.

Don’t Mix with Other Chemicals — Ever

Being in maintenance, I learned that mixing strong cleaners feels efficient, but that shortcut risks lives. Calcium hypochlorite will react with acids, ammonia, or oil-based products, sometimes explosively. Local fire codes reflect this wisdom for a reason. Never store calcium hypochlorite anywhere near corrosives, solvents, gasoline, or any organic products. Even buckets or tools used with other chemicals should stay far away unless thoroughly cleaned.

The U.S. National Fire Protection Association and OSHA both spell out rules for distance and separation: at least ten feet from combustibles and as far away as possible from acids. Walls or separate rooms work best, especially at commercial sites.

Ventilation and Containers: Details That Can Not Be Overlooked

Well-ventilated spaces reduce the risk of gas buildup, which not only protects your nose but can save your lungs from long-term damage. Never store calcium hypochlorite in sealed, airtight rooms. Fumes can build pressure and lead to dangerous bursts or leaks.

Original containers do a good job of holding up, but if they break or tear, replace them with chemical-resistant plastic drums. Never use food containers or anything not labeled for chemical storage, as trace residues can cause reactions you might not expect.

Simple Solutions Keep Everyone Safer

Clear signage helps, especially in shared storage buildings. I’ve seen success with locked cabinets labeled in both English and other languages common in the workforce. Training staff matters just as much as rules on the wall; routine safety drills sharpen everyone’s memory about what to do in case of a spill or smoky odor.

Local fire departments often offer to inspect setups and suggest low-cost improvements. Re-using advice from their expertise doesn’t cost much, but it can make the storage area safer for everyone—from workers to nearby families. For those responsible for pool chemicals at home, the same rules apply. Don’t stash pool shock in the kitchen pantry or garden shed with the mower fuel.

Taking every precaution isn’t overkill. It’s the only way to keep a powerful helper from turning into a hazard.

What Calcium Hypochlorite Brings to the Table

Any pool owner will recognize the sharp scent and potent punch of calcium hypochlorite. Often showing up as white, grainy powder or tablets, this chemical throws its weight around in pools, water treatment, and even emergency sanitation. Working with it can get messy or even dangerous, so paying attention to solid safety habits makes all the difference.

Direct Contact Carries Real Risk

A splash, a stray pinch, a breeze that whips up some dust—calcium hypochlorite is unforgiving on bare hands, exposed arms, or open eyes. Direct skin contact can burn. Let it drift into the eyes and pain turns fierce, sometimes followed by lasting damage. People sometimes underestimate the way particles float up into the air, sneaking past what looks like ordinary dust.

Gloves made from heavy nitrile or rubber offer true protection. Goggles, not just safety glasses, keep eyes out of harm’s way. Long sleeves and even a face shield can tip the odds against a wayward gust or spill. People in the trenches working water service often tell stories about coworkers ending up at urgent care because a casual “just for a second” mistake earned a chemical burn.

Mixing and Storing: A Recipe for Trouble If Unwatched

Calcium hypochlorite reacts in nasty ways with anything acidic, greasy, or organic. Pour it onto the wrong old mop or let it land on a damp floor, and you get heat, fumes, or even an explosion. Keeping it dry stands as the gold rule—containers should seal tight and never hang out near acids, cleaners, or pool chemicals like algaecides and stabilizers.

Years ago, I watched a seasoned facilities manager hit the panic button after a contractor stashed calcium hypochlorite next to pool shock tablets inside a hot shed. The air turned sharp and the lid on one drum started to bulge. Lesson learned—the stuff does not forgive a shortcut.

Inhalation Concerns and Clean-Up

Breathing in even a mild amount will leave your lungs and throat raw. In an enclosed place, dust or vapors can build up, leading to dizziness, coughing, and even chemical lung injuries. A dust mask rated for particulates or a proper respirator wipes out that risk. Open windows or good fans keep the air moving and safer for everyone.

Spills aren’t for sweeping up dry. A broom or brush sends up a cloud. Wet a pile with plenty of water, then scoop it into a safe bin lined with a sturdy bag. Toss out clothes splashed by the chemical—washing machines can’t break it down, just spread it. Shower off skin and get checked out by a doctor if there’s even a hint of redness, swelling, or breathing trouble.

Emergency Ready Beats Regret

Too many workers and even home pool owners take risks because they trust their own luck. Every place that stores calcium hypochlorite needs an eyewash station and clean water close by. Clear instructions, posted right beside storage, help cut the panic in a real emergency. Safety sheets may sound boring until you’re the one reaching for a first-aid kit.

Training counts as the real backbone of safety. People need to see a demonstration, not just a handout. Time spent walking through the correct way to open, measure, and store—and what to do if something goes sideways—pays off with fewer accidents and less waste. Hearing the stories of real incidents adds a human edge that warnings on a bag can’t match.

Practical Changes for Safer Handling

If possible, replace open bins and scoops with pre-measured single-use packs. That swap alone trims both waste and exposure. Storing the chemical below eye level avoids face-level clouds and stops heavy containers from being dropped. Keep logs of everyone who handles the chemical and require sign-offs for each use.

Staying safe never comes down to one strict rule. It grows from regular, careful habits and a willingness to spend a few more minutes upfront. Calcium hypochlorite keeps water clean, but respect for the chemical and the risks it brings keeps people healthy and out of harm's way.

What Calcium Hypochlorite Really Offers

Working in rural disaster recovery, I’ve seen plenty of ways people try to clean up water in emergencies. Tablets, household bleach, high-tech filters—each has its moment. One powder that never fails to get attention from seasoned water engineers and health volunteers is calcium hypochlorite. In tablet and granular form, this compound packs a power punch for killing bacteria, viruses, and other nasties in water. It stands out for its long shelf life and the ability to handle sizable amounts of water. A little can go a long way, making it an essential in field kits and water systems for communities off the grid.

Why Dosage Matters More Than You Think

Pouring a random scoop of calcium hypochlorite into a drum isn’t just careless, it’s dangerous. This stuff is strong—usually about 65-70% active chlorine. Using too much produces water that smells like a swimming pool and can irritate the gut; too little and you’re simply wasting time. Here’s how the pros break it down: Mix about one heaping teaspoon of powdered calcium hypochlorite (about 7 grams) into a jar or can containing 200 milliliters of clean water. This mixture creates something called a “chlorine stock solution.”

This isn’t water you drink yet. Instead, stir the solution and let it settle for half an hour. Carefully pour off the clear liquid, leaving behind any gritty residues. Now take this chlorine stock and use just 40 milliliters (around two tablespoons) to treat 20 liters of water. Give it a good stir, let it stand half an hour, and the water is safe for drinking and cooking. The World Health Organization recommends aiming for about 0.5 milligrams of free chlorine per liter if there’s no organic dirt in the water. Foul smells or cloudy water happen because too much dirt inactivates chlorine, so always start with the clearest water you can find.

Chlorine and Human Health

One thing that surprises new volunteers: calcium hypochlorite doesn’t solve everything. It knocks out pathogens, sure, but chemical contamination, heavy metals, or excess organic matter—none of these will go away. Some folks worry about harmful byproducts. If you keep dosages in check, the risk stays very low. Most cities use related forms of chlorine to disinfect tap water. The target is a trace amount left after treatment—enough to keep water safe until it reaches the mouth, not enough to create health problems.

Respect the Chemical and Protect Your Community

Storage falls into the basics. Keep this chemical dry, away from sunlight, and far from oils or acids. Letting it mix with fuel or organic materials can spark dangerous reactions. I’ve learned to double-bag and store calcium hypochlorite well above ground, locked away from animals and small children. Working in the field, a few minutes to double-check labels and instructions can save a whole team from disaster.

Building Confidence and Getting Results

Safe water doesn’t have to rely on imported filters or complicated gadgets. In relief camps, schools, and remote clinics, calcium hypochlorite gives people a tool that doesn’t break, doesn’t need batteries, and works at the scale of a family or a whole village. Guidance from experts like the Centers for Disease Control and World Health Organization has helped local health workers train families to mix, wait, and taste-test to keep everyone healthy. Using this powder right means cleaner water, fewer sick days, and more confidence in every glass poured.

Understanding Calcium Hypochlorite

Calcium hypochlorite shows up on pool store shelves as a strong disinfectant, but also gets used in water treatment. Anyone handling it—at home or at work—should know that its strength doesn’t last forever. I’ve worked with small water utilities and pool owners alike who have seen their supplies gradually lose potency, sometimes wasting money or compromising water quality. The lifespan of this chemical isn’t just a technical detail; it’s a matter of safety, budget, and effective sanitation.

Shelf Life — Not Just a Number

Fresh calcium hypochlorite often arrives with around 65-70% available chlorine. Stored properly in its original, tightly sealed packaging, away from heat, humidity, and direct sunlight, it can retain much of that power for a year. After twelve months, the strength usually drops. After two years, the active chlorine dwindles further. Heat and moisture accelerate this decline, sometimes cutting shelf life in half if containers get left in hot sheds or near water systems.

One experiment I saw at a local water plant compared two batches: one kept cool and dry, another stored in a leaky shed. After six months, the batch exposed to damp air had less than half the chlorine content of the carefully stored batch. The difference became obvious in water test results. There’s no substitute for tight lids and a dry, cool location.

Why Shelf Life Affects Safety and Dollars

Anyone who relies on calcium hypochlorite for disinfection risks more than lost dollars if it goes “off.” Using old or degraded product means weaker chlorine solutions, which means pools or water systems could harbor germs. Sometimes, people pour in extra chemical to compensate, but this drives up costs and introduces unpredictable results. In my experience, underestimating age or potency of this product has led to public pool operators misjudging dosages, leading to customer complaints and wasted supplies.

Beyond pools, rural water managers know the risk. Trust in the chlorine level matters. If bacteria sneak through, stomach bugs follow. Once, a small-town operator told me he learned the hard way that expired calcium hypochlorite just didn’t do the job, despite the fact it looked fine and didn’t clump.

Ways to Get the Most Out of Calcium Hypochlorite

Keeping this chemical in shape takes attention. Buy only as much as you’ll use in a year. Store it in a dry, ventilated place at moderate temperatures. Reseal containers tightly every time. Use the oldest product first—a practice large water plants and careful pool owners both swear by. If you spot powder that’s clumped, damp, or faded, assume it’s lost some punch and check the chlorine content with a test kit or small trial batch.

Fact: the U.S. Environmental Protection Agency points out that active chlorine declines faster above 30°C (86°F) and with moisture. Suppliers usually stamp the packaging with a date. Trust those dates. The fresher, the better. Laying in a huge supply for the season gives false security if the end of the pile barely works months later.

Smart Planning Protects Health and Wallets

Reliable treatment needs reliable chemicals. Old calcium hypochlorite doesn’t just dissolve slowly; it can upset dosing and leave water unprotected, which no one wants—especially in pool or drinking water. Keeping an eye on age, storage, and using test kits offers the only real insurance. New supplies cost less in the long run than risking ineffective disinfection or wasted effort.